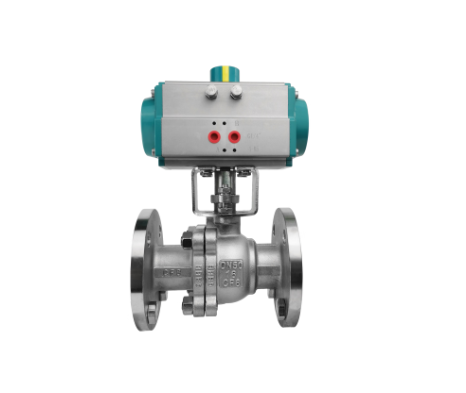

良工氣動法蘭球閥概述:

動法蘭(lan)球(qiu)(qiu)閥是一(yi)種轉(zhuan)角為90度的旋轉(zhuan)類(lei)控制閥。它由氣動活塞式執行機構(gou)和O型閥芯球(qiu)(qiu)閥組(zu)成,閥芯采用圓柱型通孔球(qiu)(qiu)體,以密封材質分(fen)有(you)軟密封和硬密封兩種。

氣(qi)動(dong)法蘭球閥(fa)以壓縮空氣(qi)為動(dong)力源,接受集散控制系統(tong)(DCS),可編程控制器(qi)(PLC)等開關信(xin)號,通過(guo)電磁閥(fa)可實(shi)現對閥(fa)門快速位(wei)式(shi)控制。

氣(qi)動(dong)法(fa)蘭球(qiu)(qiu)閥采用(yong)(yong)(yong)直通型鑄造閥體(ti),球(qiu)(qiu)面經(jing)特殊工(gong)(gong)藝加工(gong)(gong)和硬化處理(li),使其表面平(ping)滑耐磨,具有壽命長、結構緊湊、動(dong)作可靠、流通能力大、流阻系數小、安裝方便(bian)及良好(hao)的切(qie)斷功能和克(ke)服較大壓差等(deng)特點。產品廣泛用(yong)(yong)(yong)于(yu)造紙、石化、冶金、航天、食品、醫藥、水處理(li)等(deng)行業,特別(bie)適用(yong)(yong)(yong)于(yu)高(gao)黏度和含有纖維介質(zhi)的工(gong)(gong)藝控制。

氣動活(huo)塞式執(zhi)行機(ji)構(gou)可分為單作(zuo)(zuo)(zuo)用(yong)(yong)和雙作(zuo)(zuo)(zuo)用(yong)(yong)兩種。雙作(zuo)(zuo)(zuo)用(yong)(yong)氣動執(zhi)行機(ji)構(gou)在使用(yong)(yong)過程(cheng)中失氣時,閥門保(bao)持于(yu)失氣時位(wei)(wei)置,以(yi)確保(bao)繼續生(sheng)產。單作(zuo)(zuo)(zuo)用(yong)(yong)在失電或失氣時,閥門處(chu)于(yu)原(yuan)始極限位(wei)(wei)置(全(quan)開或全(quan)關),以(yi)確保(bao)生(sheng)產過程(cheng)處(chu)于(yu)安(an)全(quan)位(wei)(wei)置。

良工閥門氣動法蘭球閥零件材料:

序號(hao) | 零(ling)件名稱 | 材質(zhi) | ||

C | P | R | ||

1 | 右閥體 | WCB | ZG1Cr18Ni9Ti | ZG1Cr18Ni12Mo2Ti |

2 | 螺母 | 35 | 1Cr18Ni9Ti | 1Cr18Ni9Ti |

3 | 墊片 | PTFE、石墨金屬復合墊 | ||

4 | 螺栓 | 35 | 1Cr18Ni9Ti | 1Cr18Ni9Ti |

5 | 閥體 | WCB | ZG1Cr18Ni9Ti | ZG1Cr18Ni12Mo2Ti |

6 | 閥(fa)座 | PTFE、尼龍、對位聚苯(ben)、硬(ying)質(zhi)合金 | ||

7 | 球體 | 1Cr18Ni9Ti | 1Cr18Ni9Ti | 1Cr18Ni12Mo2Ti |

8 | 閥桿(gan) | 1Cr13 | 1Cr18Ni9Ti | 1Cr18Ni12Mo2Ti |

9 | 墊片 | 1Cr18Ni9Ti | 1Cr18Ni9Ti | 1Cr18Ni12Mo2Ti |

10 | 填料(liao) | PTFE、柔性(xing)石(shi)墨(mo) | ||

11 | 襯(chen)套 | PTFE復合(he)軸承(cheng) | ||

12 | 壓(ya)蓋(gai) | WCB | ZG1Cr18Ni9Ti | ZG1Cr18Ni12Mo2Ti |

13 | 螺(luo)栓 | 35 | 1Cr18Ni9Ti | 1Cr18Ni9Ti |

14 | 螺(luo)栓 | 35 | 1Cr18Ni9Ti | 1Cr18Ni9Ti |

15 | 連接支架 | 1Cr18Ni9Ti | 1Cr18Ni9Ti | 1Cr18Ni9Ti |

16 | 螺栓(shuan) | 35 | 1Cr18Ni9Ti | 1Cr18Ni9Ti |

17 | 連接(jie)套 | 35 | 1Cr18Ni9Ti | 1Cr18Ni9Ti |

18 | 氣動裝置 | AT系列(lie)、AW系(xi)列 | ||

19 | 位(wei)置指示(shi)器 | 塑(su)料 | ||

良工閥門氣動法蘭球閥鏈接尺寸:1.6PMA

DN | 外形(xing)尺(chi)寸 | 連接法(fa)蘭尺寸 | 執(zhi)行器型(xing)號 | ||||||||

L | L1 | L2 | H | D | D1 | D2 | C | f | n-Φd | ||

15 | 130 | 141/159 | 71/83 | 204/235 | 95 | 65 | 46 | 14 | 2 | 4-Φ14 | AT050D/AT063S |

20 | 140 | 141/159 | 71/83 | 209/240 | 105 | 75 | 56 | 16 | 2 | 4-Φ14 | AT050D/AT063S |

25 | 150 | 159/211 | 83/95 | 214/256 | 115 | 85 | 65 | 16 | 2 | 4-Φ14 | AT063D/AT075S |

32 | 165 | 159/248 | 83/107 | 257/277 | 140 | 100 | 76 | 18 | 2 | 4-Φ18 | AT063D/AT088S |

40 | 180 | 211/248 | 95/107 | 274/292 | 150 | 110 | 84 | 18 | 3 | 4-Φ18 | AT075D/AT088S |

50 | 200 | 248/269 | 107/123 | 290/300 | 165 | 125 | 99 | 20 | 3 | 4-Φ18 | AT088D/AT100S |

65 | 220 | 248/315 | 107/141 | 310/335 | 185 | 145 | 118 | 20 | 3 | 4-Φ18 | AT088D/AT115S |

80 | 250 | 269/345 | 123/152 | 346/368 | 200 | 160 | 132 | 20 | 3 | 8-Φ18 | AT100D/AT125S |

100 | 280 | 345/409 | 152/172 | 378/410 | 220 | 180 | 156 | 22 | 3 | 8-Φ18 | AT125D/AT145S |

125 | 320 | 409/550 | 172/215 | 425/450 | 250 | 210 | 184 | 22 | 3 | 8-Φ18 | AT145D/AT190S |

150 | 360 | 550/660 | 215/240 | 468/531 | 285 | 240 | 211 | 24 | 3 | 8-Φ22 | AT190D/AT210S |

200 | 400 | 600/633 | 240/262 | 583/618 | 340 | 295 | 266 | 24 | 3 | 12-Φ22 | AT210 |